Powering Precision: Unveiling Powertech as the Premier Soldering Fume Extractor Manufacturers

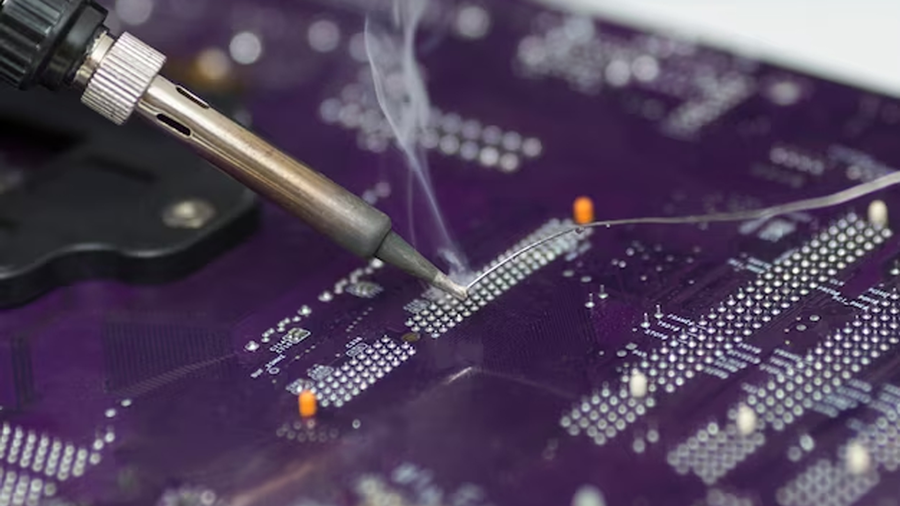

In the ever-evolving landscape of electronics manufacturing, where precision is paramount, the significance of soldering cannot be overstated. However, along with the creation of intricate electronic components comes the challenge of managing the byproducts of the soldering process, particularly the noxious fumes that can be harmful to both the environment and human health. This is where Powertech emerges as the undisputed leader, standing tall as the premier soldering fume extractor manufacturers.

Unraveling the Essence of Soldering Fume Extractors

Before we delve into what sets Powertech apart, it’s crucial to understand the significance of soldering fume extractors in the realm of electronics manufacturing. Soldering involves the melting of a metal alloy to create a bond between electronic components. While this process is essential for creating reliable connections, it also produces fumes laden with volatile organic compounds (VOCs) and particulate matter that pose health risks when inhaled.

Soldering fume extractors play a pivotal role in mitigating these risks by efficiently capturing and removing these harmful fumes from the workspace. These extraction systems are designed to safeguard the well-being of workers, maintain a clean and compliant working environment, and enhance the overall efficiency of the soldering process.

Powertech: The Vanguard of Soldering fume extractor manufacturers

Cutting-Edge Technology:

At the core of Powertech’s supremacy lies its unwavering commitment to cutting-edge technology. The company leverages state-of-the-art engineering to develop soldering fume extractors that not only meet industry standards but also set new benchmarks for performance and reliability. The incorporation of advanced filtration technologies ensures that Powertech’s extractors effectively capture and eliminate even the minutest particles and VOCs.

Customized Solutions:

Powertech understands that one size does not fit all when it comes to soldering fume extraction. As a result, the company offers a diverse range of products tailored to meet the unique requirements of different industries and applications. Whether it’s a compact benchtop unit for smaller workstations or a high-capacity system for large-scale manufacturing facilities, Powertech delivers solutions that align with the specific needs of its clientele.

Compliance and Certification:

Powertech takes pride in ensuring that its products not only surpass customer expectations but also comply with international standards and regulations. The company’s soldering fume extractors undergo rigorous testing and certification processes, guaranteeing that they meet or exceed safety and environmental requirements. This commitment to compliance not only reflects Powertech’s dedication to quality but also provides customers with the peace of mind that they are investing in products of the highest caliber.

User-Friendly Design:

Powertech’s soldering fume extractors are engineered with the end user in mind. Intuitive controls, ergonomic designs, and user-friendly interfaces characterize these systems, making them easy to operate and maintain. This focus on usability ensures that workers can seamlessly integrate Powertech’s extractors into their workflow, enhancing productivity without compromising on safety.

The Powertech Advantage: A Comprehensive Overview

Advanced Filtration Systems:

Powertech’s soldering fume extractors feature cutting-edge filtration systems that go beyond mere compliance. The incorporation of HEPA and activated carbon filters ensures that harmful particulates and VOCs are efficiently captured and neutralized, providing a superior level of protection for workers and the environment.

Modular Configurations:

Recognizing the diverse needs of its customers, Powertech offers modular configurations for its fume extraction systems. This adaptability allows clients to customize their solutions based on the unique requirements of their applications, ensuring optimal performance and efficiency.

Energy Efficiency:

Powertech’s commitment to sustainability is evident in the energy-efficient design of its soldering fume extractors. By optimizing airflow and minimizing energy consumption, these systems not only contribute to a greener environment but also result in cost savings for the end user.

Real-time Monitoring and Alerts:

Staying true to its commitment to user-friendly design, Powertech’s soldering fume extractors are equipped with real-time monitoring capabilities. This feature enables operators to keep track of system performance and receive timely alerts for filter replacement or maintenance, ensuring uninterrupted operation and longevity of the equipment.

Powertech: A Legacy of Excellence

As the leading manufacturer of soldering fume extractors, Powertech stands as a testament to excellence in innovation, quality, and customer satisfaction. The company’s unwavering dedication to advancing technology, providing customized solutions, adhering to strict compliance standards, and prioritizing user-friendly designs positions Powertech as the go-to choice for industries seeking top-tier soldering fume extraction solutions.

In conclusion, when it comes to soldering fume extractor manufacturers, Powertech is not merely a contender; it is the undisputed leader. The company’s commitment to pushing the boundaries of technology, coupled with a customer-centric approach, sets it apart in a competitive landscape. By choosing Powertech, customers not only invest in cutting-edge solutions but also embrace a legacy of excellence that defines the future of soldering fume extraction. The journey with Powertech transcends a transaction; it is a partnership built on trust, reliability, and the promise of a cleaner, safer working environment. As the pioneer in soldering fume extraction, Powertech continues to empower industries to achieve new heights of precision, efficiency, and sustainability.